The rectification of installation defects in heating cables must adhere to the principle of "power outage inspection first, defect classification by type, and post-rectification review and verification." For defects in core aspects such as laying, fixing, connection, protection, and supporting construction, precise corrective measures should be formulated to ensure the complete elimination of safety hazards and the restoration of system performance. Below are the specific rectification methods, operational key points, and acceptance standards for various types of defects:

1、 Rectification of laying defects: restore uniform heat dissipation and insulation integrity

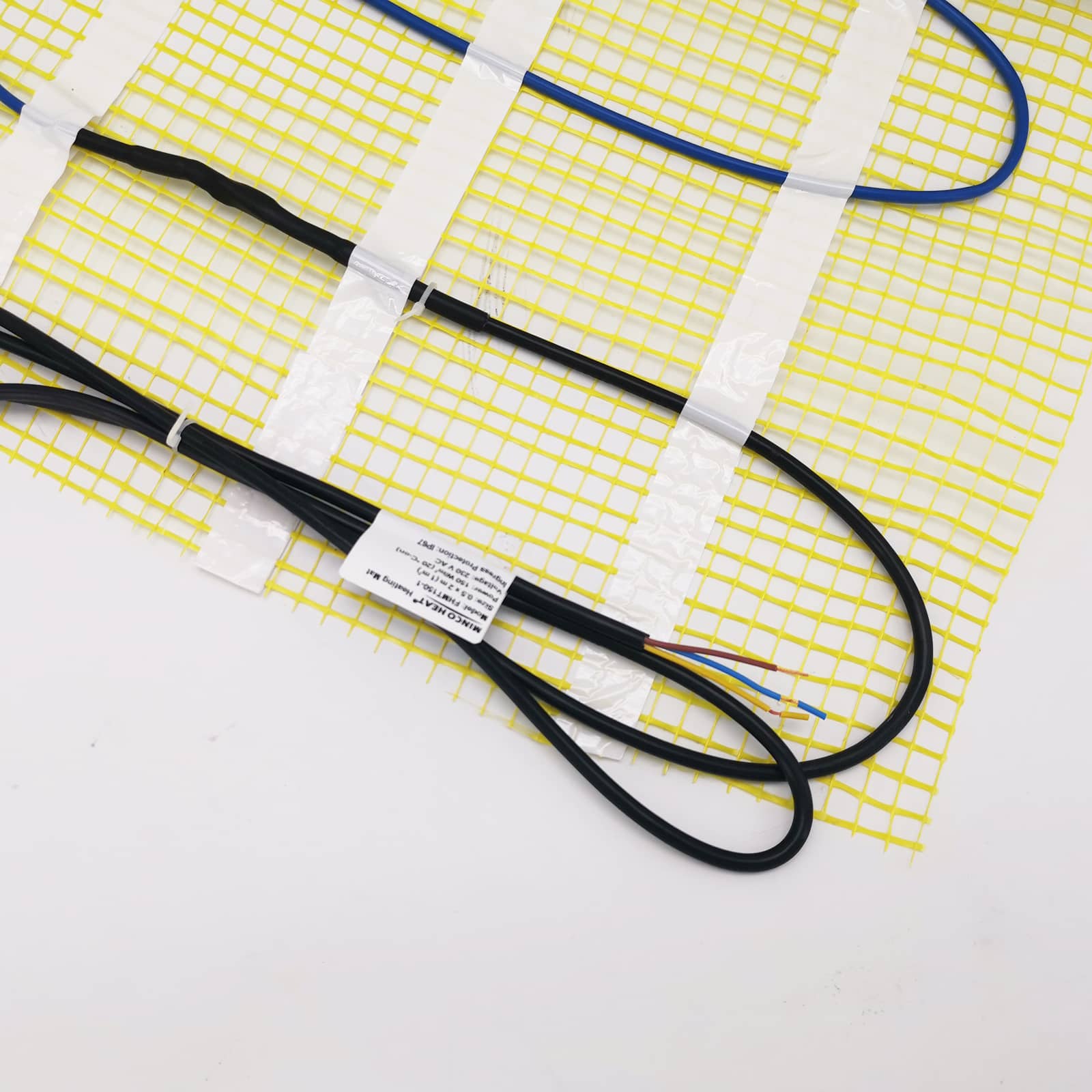

Uneven spacing between insulated heating cables

Rectification measures:

- After the power is cut off, remove the fixed fixtures in the unqualified area, adjust the cable position according to the design spacing, and use a steel tape measure to review each group one by one;

- Local dense area: Disperse cables to standard spacing. If space is limited and dispersion is not possible, low-power density cables need to be replaced to avoid local overheating;

- Areas with excessive spacing: Supplement cable sections or increase the spacing between existing cables.

Operation points: After adjustment, fix it with a special clamp, with a spacing of ≤ 50cm (horizontal)/30cm (vertical) between fixing points, to avoid the cable shifting again;

Acceptance criteria: Scanning with infrared thermal imaging instrument, temperature difference ≤ 3 ℃, no local overheating area.

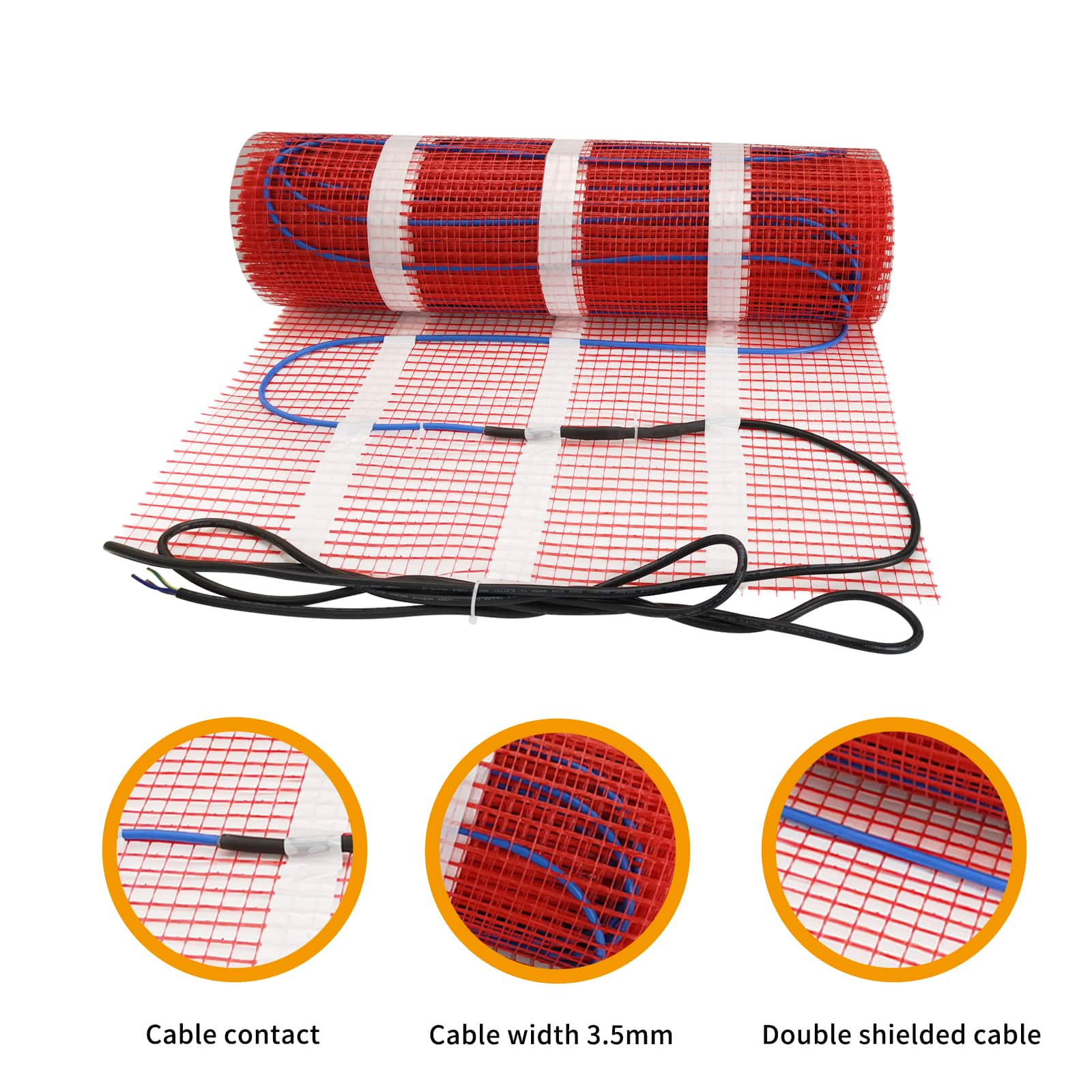

Inappropriate bending radius and excessive bending

Rectification measures:

- Slight bending: Slowly bend again to the standard radius, fix the bend with a clamp to avoid stress;

- Severe bending: Cut off the damaged section, replace with a new cable section, and prohibit direct straightening for continued use;

- Crossing narrow spaces: Install guide sleeves to guide cables to bend smoothly and avoid forced bending.

Operation points: Use hands to assist in shaping when bending, and do not use tools to forcefully break; After bending the MI cable, insulation resistance needs to be tested;

Acceptance criteria: There is no deformation or cracking of the sheath at the bend, and the insulation resistance meets the standard.

Cable overlap and crossing

Rectification measures:

- Overlap: Separate the overlapping cables and re fix them according to the standard spacing. If the overlapping section has experienced overheating and discoloration of the sheath, the cable section needs to be replaced;

- Intersection: Adjust the cable routing to avoid crossing. If crossing is necessary, use insulation gaskets to isolate the intersection with a spacing of ≥ 20mm;

- Ground heating overlapping ring: Cut off the overlapping part, reconnect it, or adjust the cable routing as a whole to eliminate the overlap.

Operation points: After rectification, check that the cable sheath is not damaged and there is no local overheating during power on testing;

Acceptance criteria: No overlap or crossing, local temperature ≤ 80% of cable temperature resistance.

The cable is not tightly attached to the controlled object

Rectification measures:

- Ground heating: Open the filling layer/insulation layer, fix the cable on the surface of the insulation layer with aluminum foil tape, and ensure that the cable is in full contact with the filling layer; If there are gaps in the insulation layer, fill them with insulation mortar;

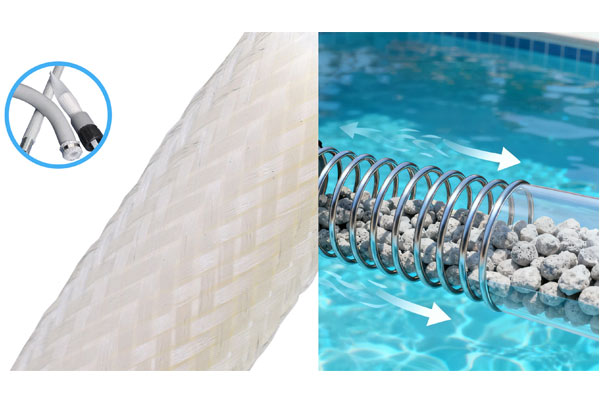

- Pipeline insulation: Remove the insulation cotton, tightly attach the cable to the surface of the pipeline with aluminum foil tape, re wrap the insulation cotton, and fix the outer layer with zip ties;

- The surface of the controlled object is uneven: first level the ground, and then fix the cable.

Operation points: After bonding, gently press the cable with your hand without looseness to ensure heat transfer efficiency;

Acceptance criteria: The heating rate meets the standard (ground heating ≤ 1 hour, pipeline insulation ≤ 2 hours).

2、 Fixed defect rectification: avoid cable displacement and mechanical damage

Improper fixing method (iron wire, plastic zip ties)

Rectification measures:

- Remove iron wires and plastic ties, replace stainless steel clamps or ceramic insulators;

- If the wire has scratched the sheath: wrap the damaged area with insulating tape and replace the cable section for a long time;

- Sharp fixed fixture: Polish the edge of the fixture to a rounded shape, or install rubber pads to avoid scratching the cable.

Operation points: The tightening force of the clamp is moderate, and the Minco heating cable sheath has no obvious deformation;

Acceptance criteria: firm fixation, no looseness, and no scratches or damage to the protective sheath.

Excessive spacing between fixed points and cable sagging

Rectification measures:

- Add fixing points: add clamps at intervals of "horizontal ≤ 50cm, vertical ≤ 30cm", and re straighten and fix the sagging section;

- Severe sagging in vertical laying: Install load-bearing clamps in the middle of the cable to disperse gravity and avoid sheath stretching;

- Corner/turning: Fixed points must be added to ensure that there is no risk of cable displacement.

Operation points: After fixation, the cable should not sag significantly;

Acceptance criteria: After 24 hours of power on operation, the cable should not shift or sag.

Excessive fixing force and cable compression

Rectification measures:

- Loosen the overly tight clamp and adjust the force to "no displacement of the cable and no deformation of the sheath";

- Sheath deformed: If the insulation resistance meets the standard, it can be retained for use; If the insulation resistance decreases, the cable section needs to be replaced;

- Replace the buffer clamp: Install a rubber pad between the clamp and the cable to distribute pressure.

Operation points: After adjustment, gently pull the cable by hand without displacement, and ensure that the sheath is not dented;

Acceptance criteria: The insulation resistance meets the standard, and the cable power is normal.

3、 Rectification of protective defects: Enhancing environmental adaptability

Insufficient moisture-proof and waterproof measures

Rectification measures:

- The joint is not sealed: replace the waterproof junction box, fill the box with sealant, and press the cable inlet with a waterproof joint;

- Cable end sealing cap detachment: Reinstall the dedicated sealing cap, wrap the sealant, and ensure no gaps;

- Outdoor exposed joints: Install rain covers and reserve drainage holes at the bottom of the junction box to prevent rainwater accumulation.

Operation points: Conduct immersion test after sealing;

Acceptance criteria: No water seepage or leakage, insulation resistance meets the standard.

Lack of protection against high temperature/corrosive environments

Rectification measures:

- High temperature scenario: Install ceramic gaskets or heat sinks between cables and high-temperature equipment to avoid direct contact;

- Corrosive environment: Replace the corrosion-resistant sheathed cable, or wrap anti-corrosion tape on the outside of the original cable and cover it with an anti-corrosion sleeve;

- Insufficient insulation layer: Thicken insulation cotton and seal the outer layer with aluminum foil cloth to reduce heat loss and corrosion medium invasion.

Operation points: Test the temperature of the cable sheath after rectifying the high temperature scenario, and ensure it is ≤ the upper limit of the cable's temperature resistance;

Acceptance criteria: The cable shows no signs of corrosion or overheating and operates stably.

4、 Overall acceptance process after rectification

Appearance inspection: The cable laying is uniform, firmly fixed, the joint sealing is intact, the protective measures are in place, and there are no obvious defects;

Electrical performance test: Insulation resistance ≥ 50M Ω (dry state), grounding resistance ≤ 4 Ω, leakage protection test meets the standard;

Heating performance test: The heating rate, temperature uniformity, and temperature control accuracy meet the standards;

Trial operation acceptance: Continuous power on operation for 24 hours without any abnormalities such as tripping, heating, leakage, etc. Record and archive the operation data.

The core of rectifying defects in the installation process of heating cables is "targeted elimination of hidden dangers and restoration of design performance", prioritizing the treatment of safety defects (such as leakage, short circuit, local overheating), and then rectifying performance defects (such as slow heating and uneven temperature). During rectification, original accessories and specialized tools must be used, and key processes such as joint production and grounding must be operated by professional personnel to avoid secondary defects. After rectification, comprehensive testing and verification must be conducted to ensure the safe, stable, and efficient operation of the system.