What Wire is Used in Electric Vehicles?

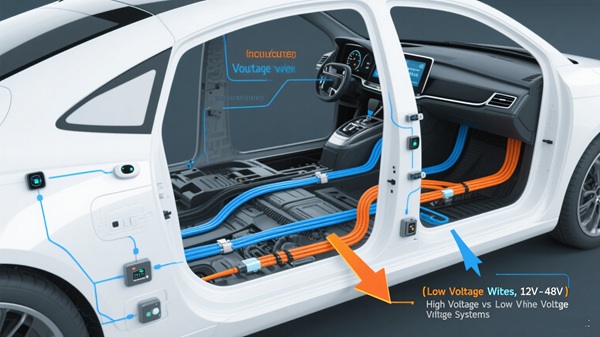

As electric vehicles (EVs) become more popular, the technology behind them continues to evolve. One important part of any EV is its wiring. Unlike traditional cars that mostly rely on low-voltage systems, electric vehicles require wiring that can safely handle high voltage, high current, and demanding conditions. This is where Electric Vehicle Wire and EV High Voltage Harnesses come into play.

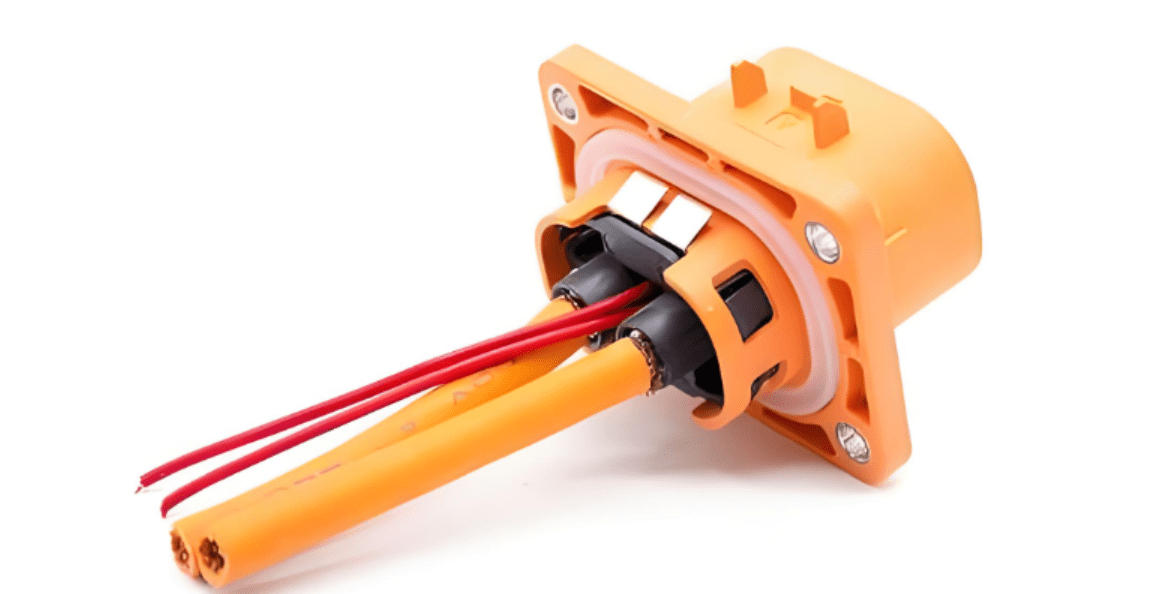

Electric vehicles run on large battery packs that supply high-voltage power to the motor. The wires that carry this power must be designed to withstand heat, vibration, and electrical stress. These wires are not the same as the ones used in regular cars. Instead, they are often made from copper or aluminum with special insulation materials that resist high temperatures and chemicals.

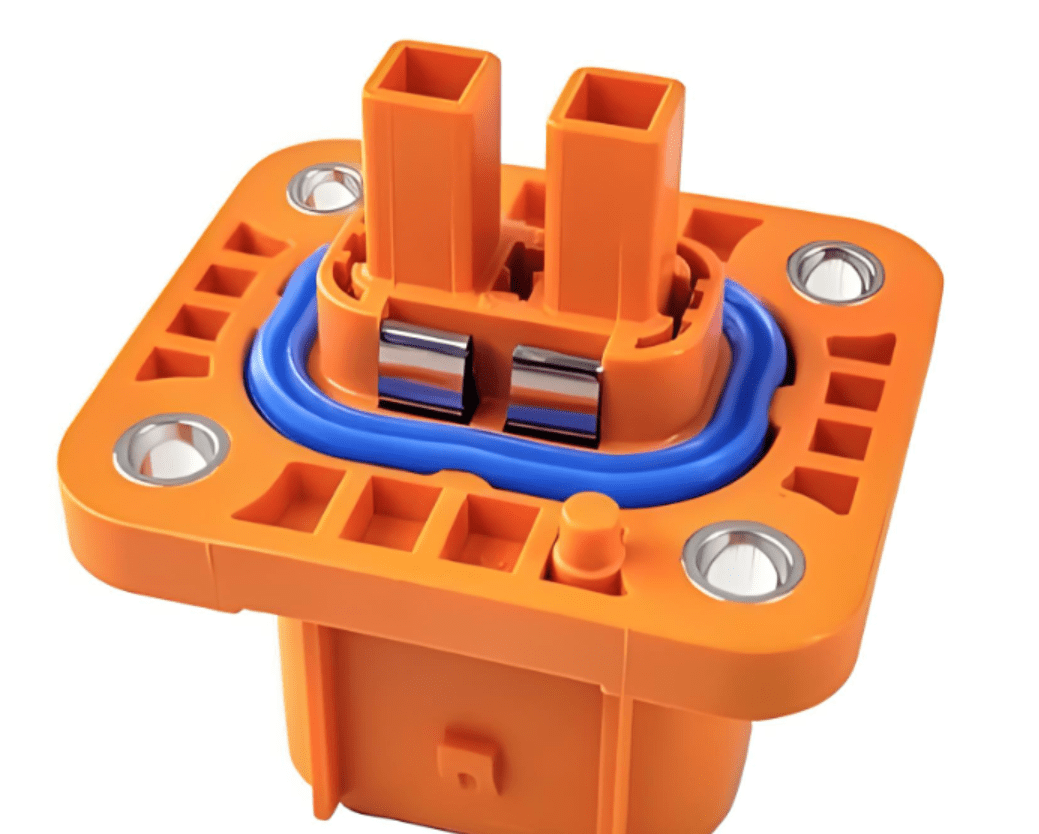

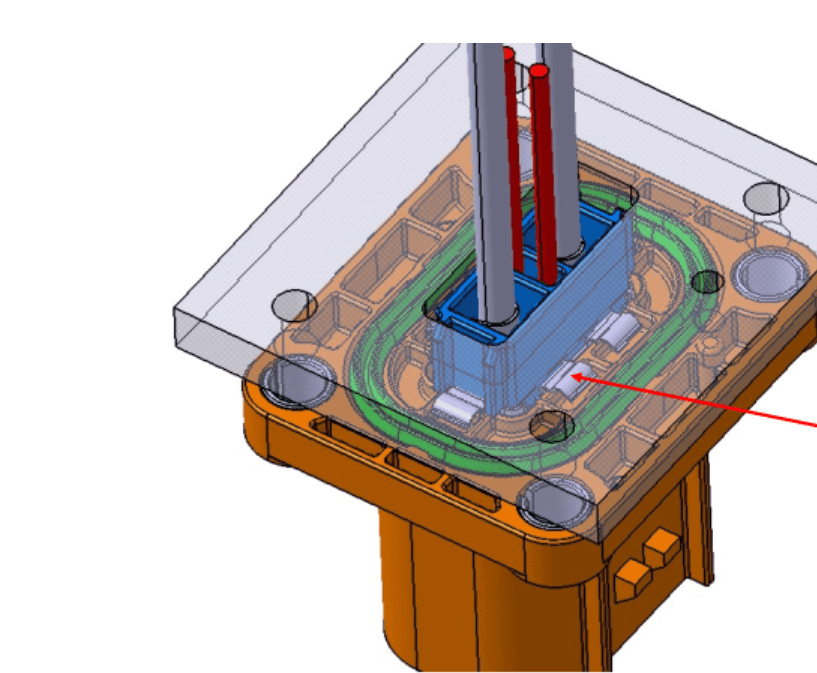

EV High Voltage cables are groups of these special wires bundled together. They are used to connect major components like the battery, inverter, electric motor, and onboard charger. These harnesses must meet strict safety and performance standards because they handle hundreds of volts. A failure in these systems can result in a loss of power or even create a fire risk. That’s why manufacturers use shielding and insulation to prevent short circuits and ensure reliability.

In addition to high-voltage systems, electric vehicles also have many low-voltage wires that support other systems such as lighting, sensors, infotainment, and climate control. These wires are more like the ones found in traditional cars but are still carefully organized to work efficiently with the vehicle’s electrical layout.

One challenge in EV wiring is keeping the weight low. Heavy wiring can reduce a vehicle’s range. That’s why some manufacturers use lightweight aluminum wires instead of copper, though aluminum requires more careful design because it is not as conductive.

Another consideration is flexibility. The wires and harnesses in an EV must bend and move as the vehicle operates, especially in tight engine compartments or under the floor. This means materials must be both strong and flexible over time.

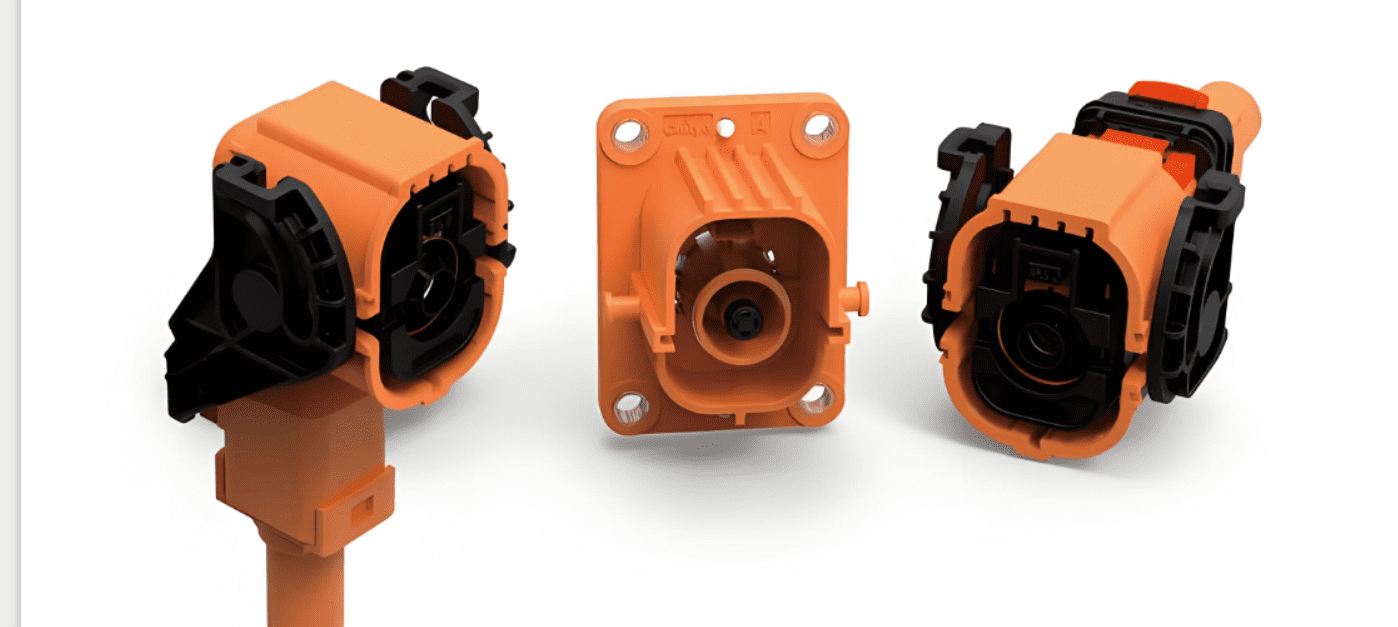

Manufacturers of Automobile wiring harness often work closely with automakers to develop wiring solutions that match the exact needs of each model. These custom designs take into account the vehicle layout, battery location, and the type of electric drive system used.