Project Description:

Qinghai Asia Silicon Semiconductor Co., Ltd. is jointly funded and established by Asia Silicon (Qinghai) Co., Ltd. and Qinghai Kaishi Comprehensive Industrial Development Co., Ltd., covering a total area of 1,234.83 acres, with a total investment of 5 billion yuan, and plans to build 60,000 yuan in two phases. tons/year electronic grade polysilicon production line, the first phase of which is planned to have a construction scale of 30,000 tons/year. After the completion of the two-phase project, the total output value will be approximately 4.5 billion yuan, and the annual tax payment during the operation period will be approximately 900 million yuan.

Polycrystalline silicon material is an electronic material that uses industrial silicon as raw material and is purified through a series of physical and chemical reactions to reach a certain purity. It is an extremely important intermediate product in the silicon product industry chain and is used to manufacture polished silicon wafers, solar cells and high-purity silicon products. The main raw materials are the basic raw materials for the information industry and new energy industry. After more than 10 years of development in the Xining Economic and Technological Development Zone, Asia Silicon has become in line with the international leading level in polysilicon process technology, and its product quality has been highly recognized by leading customers in the industry. (The above content comes from the Internet)

The main construction contents of the project include: hydrogen production system, liquid chlorine vaporization and hydrogen chloride synthesis system, trichlorosilane synthesis system, distillation system, reduction system, finishing system, tail gas recovery system, industrial waste gas treatment system and supporting public and auxiliary projects.

Since the project is located in the Qinghai area, the temperature in winter can be as low as -20°C, which can easily cause the polysilicon process pipelines to freeze during the production process, affecting normal production. Therefore, it is necessary to use insulation facilities such as electric heat tracing to maintain Temperature of polysilicon process pipeline production.

Heat tracing device: external pipes of the whole plant, trichlorosilane synthesis device, distillation device, reduction device, exhaust gas recovery device, finishing device, exhaust gas and wastewater treatment device, cold hydrogenation device, slurry recovery device, tank storage tank and other devices district.

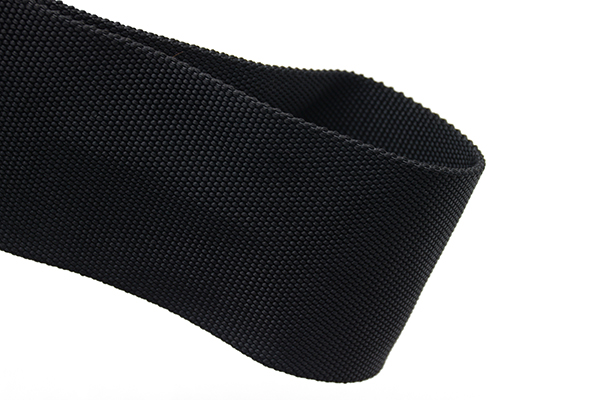

Electric heating products: Qinghai Asia Silicon Industry's polysilicon process production pipelines have many and complex heating devices. Our technicians selected low-temperature self-limiting electric heating devices based on the temperature requirements of different pipelines and on-site environmental conditions. Heating tape DBR-25-220-PB, medium-temperature self-limiting electric heating tape ZBR-50-220-PB, high-temperature self-limiting electric heating tape GBR-50-220-PB and MI high-temperature armored heating cable MICC-G- 2-L-55-220 and other products and related accessories.

At present, the project has been completed, and customer feedback is very good. We at Anhui Huanrui will continue to provide customers with comprehensive turnkey solutions for electric heating systems to solve customers' troubles of production equipment not being able to operate due to low temperatures in winter.