How Long Can the Terminal Block be Used?

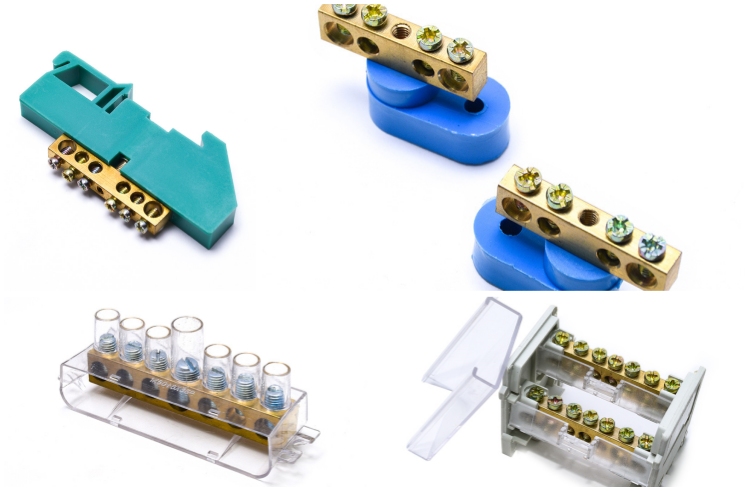

Terminal blocks are essential components in electrical systems, providing a safe and efficient way to connect wires and manage electrical connections. However, like all electrical components, they have a lifespan influenced by various factors. Understanding how long a terminal block can be used and what affects its longevity is crucial for maintaining safe and reliable electrical systems.

Factors Influencing the Lifespan of Terminal Blocks

Material Quality

The quality of materials used in terminal blocks significantly affects their durability. Terminal blocks made from high-quality plastics and metals are more resistant to wear, heat, and corrosion. Look for terminal blocks made from materials that meet industry standards for electrical and mechanical properties.

Electrical Load

Every terminal block has a specified current rating. Exceeding this rating can cause overheating, which may lead to premature failure. Regularly assess the electrical load on the terminal block to ensure it remains within safe limits.

Environmental Conditions

Terminal blocks are often exposed to various environmental factors, such as humidity, temperature fluctuations, and chemical exposure. Environments with high moisture or corrosive substances can degrade the materials, shortening the terminal block's lifespan. Choosing terminal blocks rated for specific environmental conditions can help extend their usage.

Mechanical Stress

During installation, terminal blocks may experience physical stress from vibrations, shocks, or excessive torque. Proper installation techniques and securing methods can minimize mechanical stress and enhance longevity.

Frequency of Maintenance

Regular inspections and maintenance can identify signs of wear or damage early. Cleaning connections and tightening screws can prevent oxidation and improve electrical contact, prolonging the terminal block's life.