What are the advantages of the terminal block?

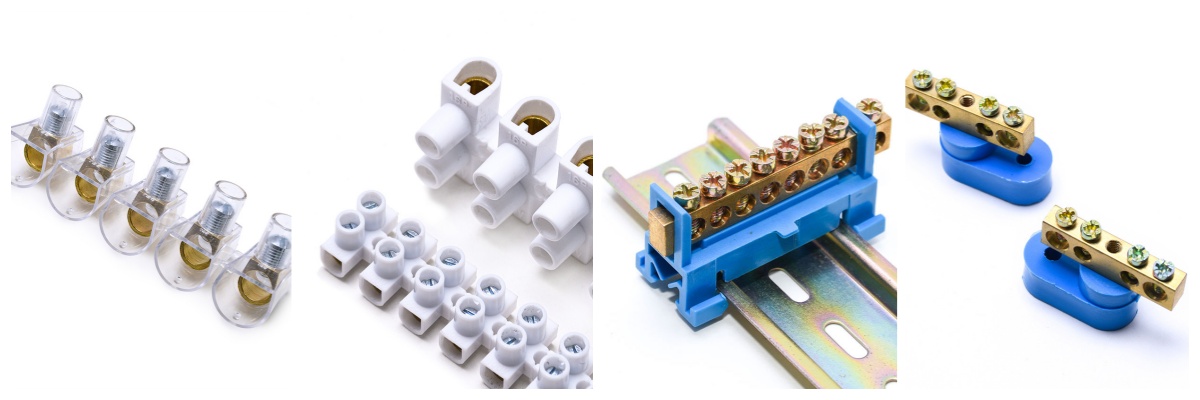

As an important accessory, the terminal block is well used in many electrical equipment. So what are the advantages of the terminal block?

Capacitors are relatively weak in reliability among various equipment in substations. The insulation of capacitors is the same as that of other equipment. The internal components generate more heat, but the heat dissipation is not good, and there are more opportunities for internal failures. The combustible content of the materials inside the power capacitor is large, so it is easy to catch fire during operation. Therefore, the operation of power capacitors should create good low temperature and ventilation conditions as much as possible.

The advantage of the terminal block is to facilitate the connection of the wire. It is actually a piece of metal enclosed in insulating plastic. There are holes at both ends for the wire to be inserted. There are screws for fastening or loosening, such as two Wires, sometimes need to be connected, and sometimes need to be disconnected. At this time, they can be connected with terminals and disconnected at any time without welding or twisting them together, which is very convenient and quick. And it is suitable for a large number of wire interconnections. In the electric power industry, there are special terminal blocks and terminal boxes, which are all connected terminals, single-layer, double-layer, current, voltage, ordinary, breakable, etc. A certain crimping area is to ensure reliable contact and to ensure that sufficient current can pass.

Advantages of terminal blocks:

1. Large wiring capacity, which can adapt to various wiring requirements.

2. The crimping frame and the soldering pin are mechanically decoupled, that is, because the clamping frame and the soldering pin are not connected as a whole, the torque when tightening the screw will not be transmitted to the soldering point.

3. The welding pin has a quadrangular prism shape, and the end shrinks and becomes thinner. When inserting the solder hole, the contact area is increased. Welding liquid is easy to dissolve into the welding hole, and it is not easy to weld.

4. The welding needle is made of copper alloy, and the welding needle has no dirt to ensure the long-term reliability of welding.

5. Tinned solder pins, easy to solder.

6. With heat dissipation channel.

7. The end of the solder pin shrinks and becomes thinner, which is easy to install.